|

Adjustable supporting table Support of the working plane with high excursion that allows working also on high models. |

|

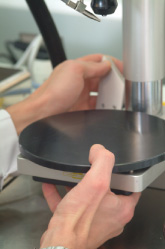

Removable locking plane AQ/52 The removable locking plane AQ52, shown in the besides picture, allows securing the model holder and, once removed, to work directly on the MULTI-PIN plane, suitable for wax milling and for ceramic materials finishing.

|

|

Micro motor with quick bur release

Motor assembly (with medium eccentricity 0.02 mm) that allows the release and the locking of the bur in a very short time (about 5 seconds), reducing the working time. |

|

Separate digital electronic feeder

It supplies the electrical feeding to the machine and is equipped with all regulation and control devices. Easily removable and multi position for several uses. |

|

Mechanical model holder AR1/M

Very big model holder granting an excellent working stability. It allows to fix and lock many different kinds of models and to work without using any transfer technique. |

|

Base locking unit |

|

Bur cooling circuit |

|

Integrated spotlight Adjustable lighting system of the machine that improves the tri-dimensional perspective of the model without shadows. Being not reflective it is less tiring. |

.jpg) |

Mandrel for attachments assembly and surveying |

|

Pneumo-electrical double pedal |

|

Air turbine with feeder |

|

TAP draining model holder |

|

• Pneumo-electrical double pedal

• Air-oil cooling assembly

• Pneumatic regulator

• Sliding disc

• Locking plane

• Milling lubricating oil

• Complete porta-chuck nut ø 2,35 mm

• Complete porta-chuck nut ø 3 mm

• Collet adapter for ø 1,6 mm burs

• Universal mandrel • Ergonomic handgrip

• Air turbine with spray

• Hydro pneumatic feeder

• Draining model holder TAP

• Pneumatic pedal

• Universal mandrel

• Complete porta-chuck nut ø 1,6 mm

• Protection rings

• MULTI-PIN draining sliding plate

• Water draining pipe

• Water collecting vessel • Water draining pipe • Accessories holder • Slideways oil

|

A4 IRON STONE

.jpg) |

|

AR1/MMD magnetic model hoder Model holder privided with switch-off magnets allowing the locking of the base on the working plane of the machine. |

|

Micrometric tracer point Device allowing a micrometric measuring of the working to be done. |

|

SPRING draining model holder |

.jpg) |

Led lamp |

A4 IRON STONE - Gold Line

| Worked materials | |

| Wax | *** |

| Resin | *** |

| Precious alloys | *** |

| Non precious alloys | *** |

| Titanium | *** |

| Implants | *** |

| Zirconia | *** |

| Technical data | |

| Machine dimensions (mm) | 320x300x470 |

| Machine Weight (kg) | 24 |

| Dimensions electronic feeder (mm) | 195x190x80 |

| Weight electronic feeder (kg) | 4 |

| Dimensions hydro pneumatic feeder (mm) | 220x170x210 |

| Weight hydro pneumatic feeder (kg) | 3,5 |

| Micro motor | |

| Speed (rpm) | 1.500÷27.000 |

| Pressure (bar) | 3÷4 |

| Air consumption (l/min) | 40 |

| Turbine | |

| Turbine speed (rpm) | 0÷300.000 |

| Turbine pressure (bar) | 2,8÷3,2 |

| Turbine air consumption (l/min) | 40 |

Printable version

Printable version  Request informations

Request informations  Tell a friend…

Tell a friend…